Environmentally Friendly Products

Developing Environmentally Friendly Products

We are committed to sustainability by offering products that support global environmental conservation.

Sales of environmentally friendly products

Approx. ¥77 billion (FY2024)

Saving Energy and Resources

E Glass Fiber (chopped strands)

Our E glass fiber improves plastic strength, heat resistance, rigidity, and dimensional stability. E glass fiber used to reduce automobile weight and enable miniaturized and thinner electronic devices.

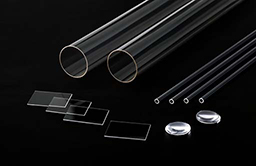

Ultra-Thin Glass: G-Leaf®, Dinorex UTG®

G-Leaf® is an ultra-thin, bendable glass with a thickness of only tens of microns. Dinorex UTG® is a ultra-thin glass for chemical strengthening developed for foldable display cover glass. The high surface smoothness and uniform thickness of these glasses allow excellent bending properties, opening the door for development of new electronic devices. These glass products also increase manufacturing process efficiency by reducing device weight and being suitable for roll-to-roll manufacturing, and saving resources by eliminating the need for chemical glass slimming processes.

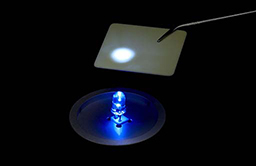

Lumiphous™ phosphor-glass composite

This wavelength-converting material expands the range of applications for energy-efficient LED lighting.

Glass powder for LTCC

(low temperature co-fired ceramics)

By incorporating highly conductive gold or silver in the inner layer of the conductor, circuit boards made with this glass powder deliver excellent electrical performance and save energy.

FireLite insulating glass

Our FireLite insulating glass is the only fire-retardant glass capable of withstanding both intense heat during a fire and rapid cooling from firefighting efforts. Combining FireLite and low-radiation glass with plastic or wooden sashes creates a highly insulated fire window that increases building and home safety, comfort, and energy performance.

Creating Energy

E Glass Fiber (roving)

This glass fiber serves as reinforcement for the plastic blades of wind turbines and shows potential for reinforcing hydrogen gas tanks in fuel-cell vehicles.

All-solid-state sodium-ion secondary battery

NEG’s proprietary glass-ceramics technology integrates the anode, cathode, and solid electrolyte, all composed of stable oxides, into a strong, unified structure. This innovative battery operates in extreme conditions (–40°C to 200°C) with no risk of fire or toxic gas emissions. Using sodium, a readily available resource, it also alleviates concerns about raw material procurement.

Ultra-thin cover glass for artificial satellite solar panels

This cover glass protects satellite solar cells from ultraviolet light deterioration in outer space while also reducing their weight.

Reducing Environmental Impact

High-efficiency deep UV transmitting glass

Designed for use in LED antiseptic lamps, this glass helps replace lamps that contain environmentally harmful mercury.