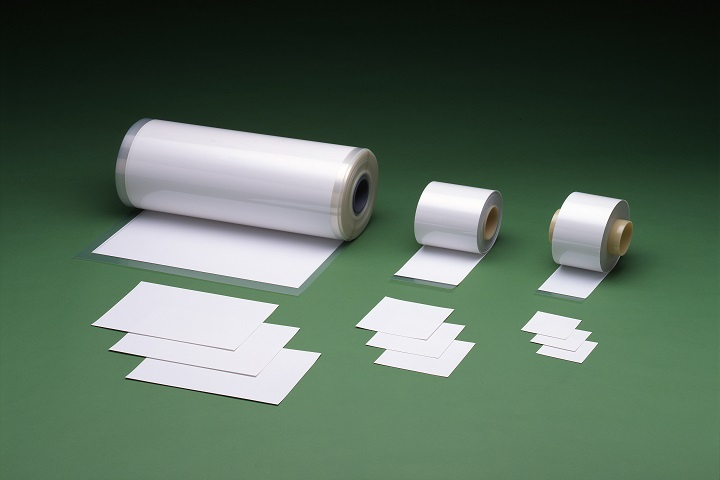

Composite Powder for Low Temperature Cofired Ceramics

Composite material blended with glass and ceramic powder

Composite Powder for Low Temperature Cofired Ceramics (LTCC) can be fired at 870 to 900°C. This allows the use of gold or silver paste, which offer high electrical conductivity, for the inner layer conductor—resulting in circuit substrates with excellent electrical properties.

Properties

-

MLS-25M: Vitreous material with a low coefficient of thermal expansion and low dielectric constant.

-

MLS-25E: Vitreous material with a dielectric constant of less than 4 and a low dielectric constant.

-

MLS-41: Devitrifiable material with a high dielectric constant.

-

MLS-23K: New product with a low dielectric constant and low dielectric loss tangent.

-

MLS-63: Devitrifiable material with high mechanical strength and low dielectric loss.

| Properties/Glass code | MLS-25M | MLS-25E | MLS-41 | MLS-23K | MLS-26 | MLS-63 | ||

|---|---|---|---|---|---|---|---|---|

| Bending strength | MPa | 157 | 125 | 250 | 150 | 320 | 400 | |

| Dielectric constant | 1MHz, 25℃ | 4.9 | 3.9 | 17.0 | 3.9 | 7.1 | 8.0 | |

| 15GHz, 25℃ | 4.8 | 3.9 | 19.0 | 4.0 | 6.7 | 7.9 | ||

| tan δ | 1MHz, 25℃ | ×10-4 | 25 | 5 | 20 | 5 | 4 | 5 |

| 15GHz, 25℃ | 47 | 21 | 50 | 15 | 58 | 11 | ||

| Coefficient of thermal expansion | 30~380℃ | ×10-7/K | 42 | 60 | 84 | 65 | 58 | 87 |

| Density* | ×103kg/m3 | 2.52 | 2.29 | 4.36 | 2.24 | 3.02 | 3.52 | |

| Transformation point | ℃ | 500 | 500 | 700 | 525 | 625 | 725 | |

| Volume resistivity Log ρ | 150℃ | Ω・cm | 13.5 | >14 | - | >13.8 | 12 | >14 |

| Thermal conductivity | W/m・K | 1.9 | 1.7 | 3.1 | 1.7 | 3.9 | 4.1 | |

| Particle size | D50 | μm | 3.3 | 3.5 | 1.1 | 1.0 | 2.6 | 1.6 |

| Dmax | 20 | 20 | 10 | 15 | 15 | 10 | ||

| Glass type | SiO2・B2O3 | Nd2O3・TiO2・SiO2 | SiO2・B2O3 | SiO2・CaO・Al2O3 | ||||

-

Powder theoretical density

Application Examples

-

Casting and Printing

Glass-ceramic powder, binder resin, solvent, and plasticizer are thoroughly mixed and cast into a 50-300μm thick green sheet using the doctor blade method. Individual sheets are cut into appropriate sizes from the green sheet and punched with via holes and then screenprinted with a circuit pattern. -

Lamination

Green sheets are laminated at 50-100°C and under 10-35 MPa pressure. -

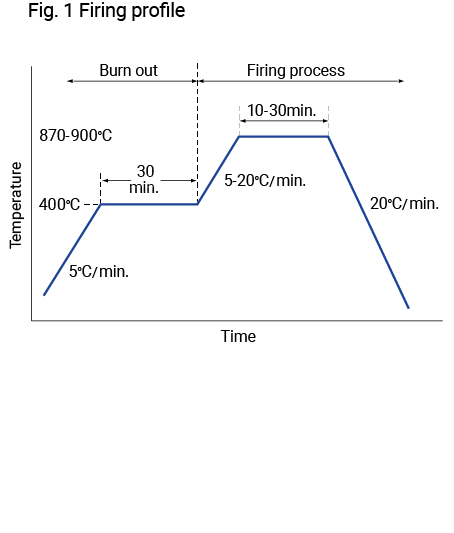

Firing

Firing is carried out in the air. [Fig. 1]

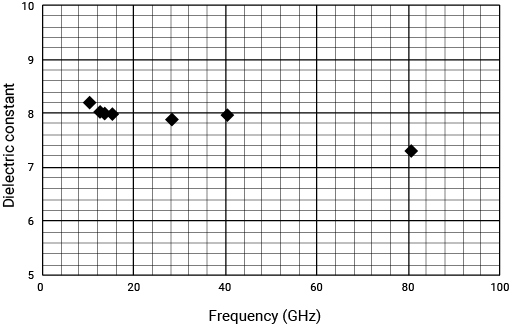

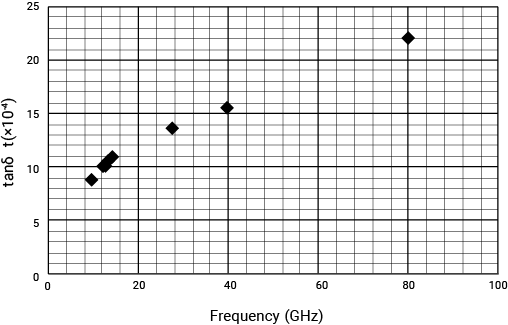

High-Frequency Dielectric Properties of MLS-63

Dielectric constant

tan δ

Event Information

We will be exhibiting at the following events.

Need More Details? Connect with Us!

Related Products

Low Temperature Sealing Glass

Granulated Glass for Metal Packages

Powder Glass for Coating, Binding, and Sealing

Tablet

Find Similar Products

Functions and Characteristics