Granulated Glass for Metal Packages

Granulated glass with excellent flowability and fillability, ideal for tablet forming process

Glass for matching seals is used with Kovar stems and leads, while those for compression seals are used with iron or stainless steel stems and leads of iron-nickel, iron-chrome alloys or Kovar. Glass for part support is used for stand-off.

Properties

| Usage | Seal | Part support | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Compression seal | Matching seal | Standoff | |||||||||

| Glass code | ST-W/K | ST-4W/K | FN-13W/K | BH-W/K | BH-7W/K | BH-8W/K | BH-14W/K | ST-4F/K | BH-FW/K | ||

| Particle size | D50 | μm | 135 | 130 | 110 | 135 | 135 | 135 | 135 | 120 | 125 |

| D99 | 265 | 250 | 215 | 265 | 265 | 265 | 265 | 235 | 245 | ||

| Firing temperature: T1 | ℃ | 650~660 | 680~690 | 700~710 | 670~680 | 730~750 | 650~660 | 750~800 | |||

| Sealing temperature: T2 | 960 | 980 | 930 | 980 | 960 | 1050 | |||||

| Coefficient of thermal expansion | 30~380℃ | ×10-7/K | 95 | 95 | 75.5 | 45.5 | 49.5 | 62.5 | 31.5 | 94 | 57 |

| Density | ×103kg/m3 | 2.60 | 2.60 | 2.51 | 2.28 | 2.32 | 2.41 | 2.13 | 2.65 | 2.83 | |

| Transformation point | ℃ | 450 | 460 | 510 | 470 | 505 | 510 | - | 460 | 515 | |

| Deformation point | 510 | 520 | 570 | 550 | 565 | 570 | - | 520 | 635 | ||

| Strain point | 420 | 427 | 480 | 435 | 472 | 475 | - | - | - | ||

| Annealing point | 460 | 472 | 517 | 480 | 513 | 520 | - | - | - | ||

| Softening point | 663 | 672 | 687 | 698 | 715 | 685 | 782 | - | - | ||

| Working point | 980 | 1030 | 990 | 1050 | 1130 | 990 | 1090 | - | - | ||

| Dielectric constant | 1MHz 25℃ | 6.4 | 6.5 | 6.3 | 5.0 | 5.5 | 5.8 | 4.0 | 6.7 | 6.4 | |

| tan δ | 1MHz 25℃ | ×10-4 | 22 | 21 | 32 | 30 | 39 | 37 | 3 | 24 | 31 |

| Volume resistivity Log ρ | 150℃ | Ω・cm | 11.4 | 11.2 | 11.2 | 11.5 | 10.8 | 11.1 | 15.5 | 11.4 | - |

| 250℃ | 8.8 | 8.7 | 8.7 | 8.8 | 8.2 | 8.5 | 12.3 | 8.8 | - | ||

| 350℃ | 6.9 | 7.0 | 7.0 | 7.0 | 6.4 | 6.8 | 10.2 | 7.0 | - | ||

| Young’s modulus | GPa | 68 | 68 | - | 57 | 57 | - | - | - | - | |

| Poisson’s ratio | 0.21 | 0.21 | - | 0.22 | 0.22 | - | - | - | - | ||

| Glass type | Na2O・BaO・SiO2 | Na2O・Al2O3・B2O3・SiO2 | Na2O・BaO・SiO2 | Na2O・Al2O3・B2O3・SiO2 | |||||||

| Application | Fe, Fe-Ni, Fe-Cr, Fe-Ni-Cr | Fe Kovar |

Kovar Mo |

Fe | Kovar | ||||||

-

ST-4F/K and BH-FW/K are composite glass (glass-ceramic).

-

Please contact us about color variations.

Application examples

-

Pressing

The appropriate molding pressure is 8 to 10 MPa. Tablets molded at this pressure offer sufficient green strength, with a porosity of 0.35 to 0.37, and allow for easy thermal decomposition of the binder during the pre-firing process. -

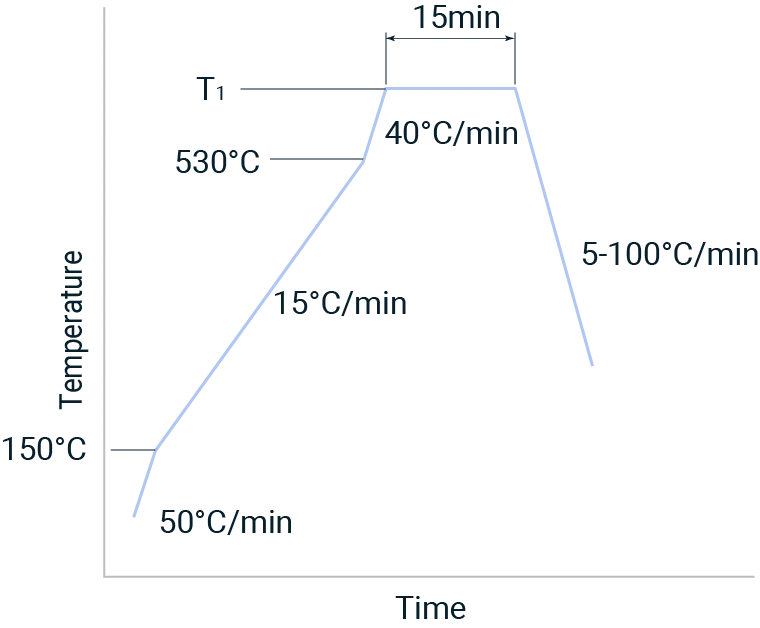

Pre-firing

Pre-firing is carried out in an oxidizing atmosphere such as oxygen or air. Refer to T1 in the property table above for the pre-firing temperature. Binder decomposition begins at 150°C and completes around 530°C, so the temperature increase rate in this range should be less than 15°C/min. Following the pre-firing schedule in Figure 1, the shrinkage of a tablet molded at 8 to 10 MPa pressure will be between 13.5% and 14.5%.

Figure 1 Pre-firing profile

-

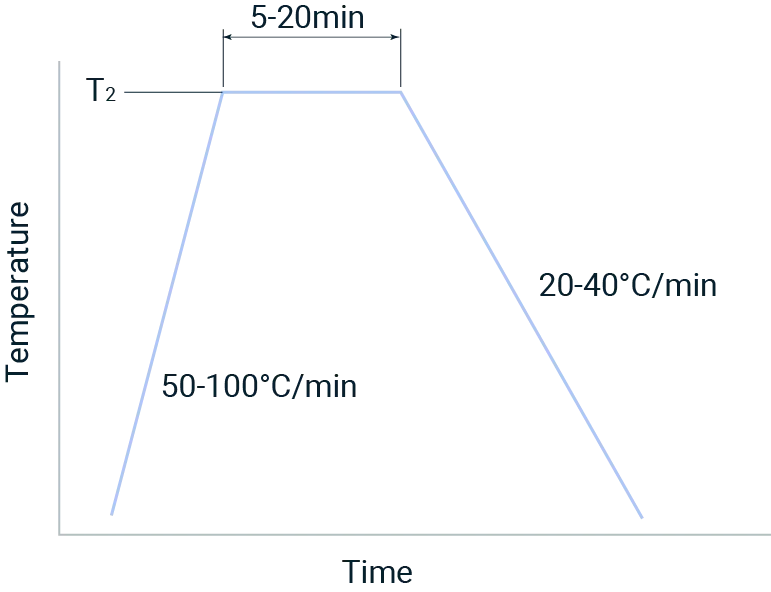

Sealing

Sealing is carried out in nitrogen atmosphere. Refer to T2 in the property table above for the appropriate sealing temperature.

Figure 2 Sealing profile

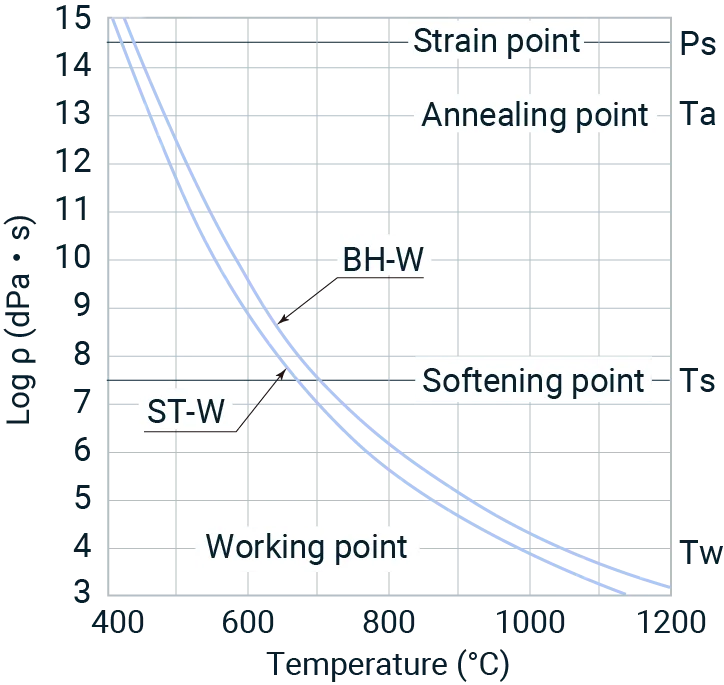

Figure 3 Viscosity

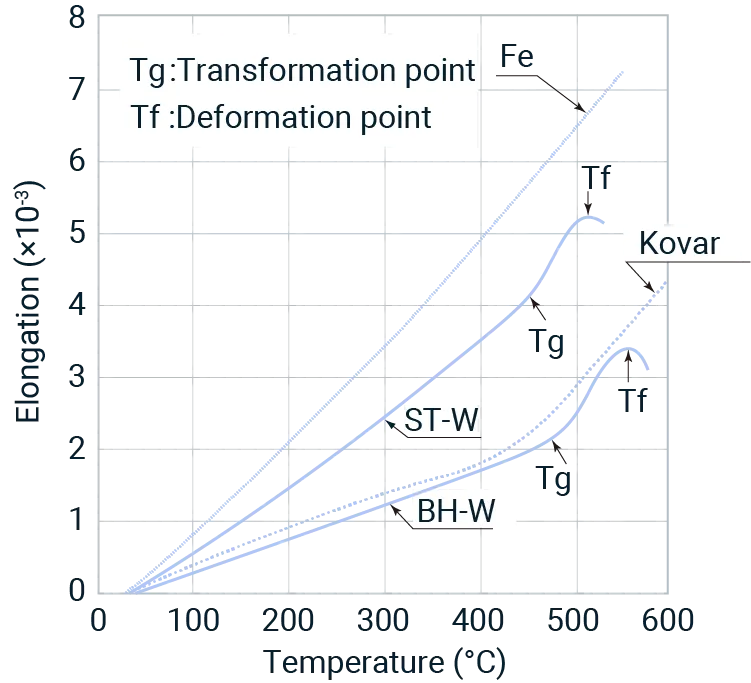

Figure 4 Thermal expansion

Need More Details? Connect with Us!

Related Products

Low Temperature Sealing Glass

Passivation Glass

Composite Powder for Low Temperature Cofired Ceramics

Powder Glass for Coating, Binding, and Sealing

Find Similar Products

Functions and Characteristics

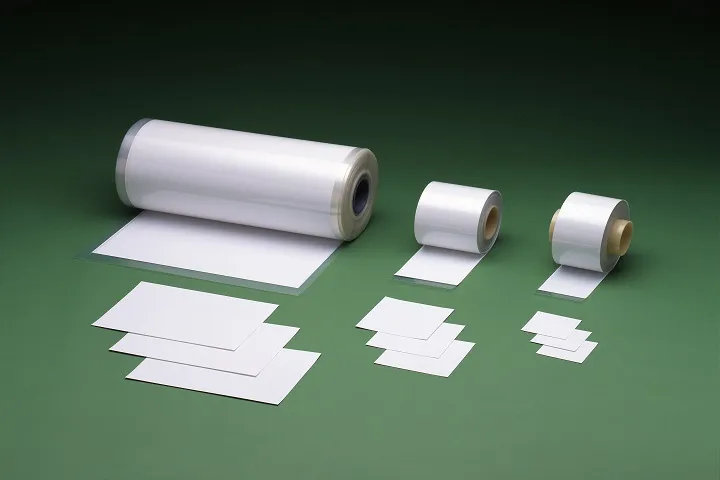

Shape