Low Temperature Sealing Glass

Tailored to sealing temperature and coefficient of thermal expansion requirements

Sealing glass is made by blending low-softening point glass powder with special ceramic powder. By adjusting the combination and blend ratio of these powders, we can achieve a variety of sealing temperatures and coefficients of thermal expansion to meet specific requirements.

Properties 1

-

LS-2010 is widely used for DIPs and QFPs made from alumina, which has a coefficient of thermal expansion of approximately 70×10⁻⁷/K.

-

LS-1401S, with a sealing temperature of 380°C, is ideal for SMD packages used in quartz crystal oscillators, where low-temperature sealing is particularly beneficial.

-

LS-3051S is suitable for low expansion ceramics like aluminum nitride, which has a coefficient of thermal expansion of about 45×10⁻⁷/K.

-

LS-1301 and BF-0901 are used for applications involving silicon.

| Application | Alumina | Aluminum nitride, mullite, silicon | |||||

|---|---|---|---|---|---|---|---|

| Properties/Glass code | LS-1401S | LS-2010 | LS-3051S | LS-1301 | BF-0901 | ||

| Sealing temperature | ℃ | 380 | 435 | 430 | 450 | 560 | |

| Dielectric constant | 1MHz, 25℃ | 45.0 | 12.5 | 16 | 45.5 | 11.1 | |

| tan δ | 1MHz, 25℃ | ×10-4 | 38 | 34 | 41 | 60 | 19 |

| Coefficient of thermal expansion | 30-250℃ | ×10-7/K | 71*1 | 65 | 51 | 41 | 49*2 |

| Transition point | ℃ | 258 | 313 | 303 | 315 | 430 | |

| Softening point | ℃ | 355 | 400 | 390 | 390 | 528 | |

| Density | ×103kg/m3 | 7.02 | 5.67 | 5.95 | 6.77 | 4.69 | |

| Volume resistivity Log | 150℃ | Ω・cm | 6.2 | 12.4 | 12.7 | 12.0 | 13.3 |

| Thermal conductivity | W/m・K | 0.98 | 1.45 | 1.24 | 0.84 | 1.47 | |

| Specific heat | ×103J/kg・K | 0.34 | 0.41 | 0.38 | 0.35 | 0.46 | |

| Acid resistance | 20%H2SO4, 70℃, 1min | mg/cm2 | ー | 0.8 | 1.1 | 0.1 | ー |

| 10%H2SO4, 20℃, 10min | mg/cm2 | ー | 0.5 | 0.9 | 0.1 | ー | |

| 10%HCl, 20℃, 10min | mg/cm2 | ー | 1.9 | 2.7 | 0.5 | ー | |

| 10%HNO3, 20℃, 12min | mg/cm2 | ー | 120 | 120 | 123 | ー | |

| Color tone | Black | Brown tint | Black | Black | Green | ||

| Glass type | PbO and B2O3 (composite) | Bi2O3 and B2O3 (composite) | |||||

-

Coefficient of thermal expansion is measured in the range of 30 to 200°C

-

Coefficient of thermal expansion is measured in the range of 30 to 300°C

For lead-free options or additional properties not listed above, please contact us.

Usage Examples

-

Printing and Drying (Except LS-1401S)

Add a vehicle to the powder glass and mix thoroughly to form a paste. A suitable vehicle is a low-molecular-weight acrylic resin dissolved in 5% terpineol. Use a stainless steel screen with an 80–100 mesh size for printing. Dry the printed material at 120°C for 10–20 minutes. Repeat the printing and drying process until the desired coating thickness is achieved. -

Temporary Baking

Carry out temporary baking in air or oxygen to remove the resin from the coating film. Since the decomposition and firing of acrylic resin are most active between 320°C and 380°C, increase the temperature gradually within this range. Maintain the peak temperature for about 10 minutes to ensure complete resin removal. -

Lead Sticking

Perform lead sticking in air, holding the material at the solidification temperature for 5–7 minutes. If using a heater block, set the block surface temperature 30–50°C higher than the sticking temperature and hold for 1–2 minutes. -

Sealing

Conduct sealing in air or nitrogen and maintain the material at the sealing temperature for approximately 10 minutes.

For additional details, please refer to the downloadable document.

Property 2

-

Composite System

Our sealing glass can bond various glass substrates and metals efficiently in a short time. -

Crystallinity

Crystalline glass is produced by growing crystals within softened, flowing glass. It’s possible for the glass to maintain its shape during reheat processing.

| Properties/Glass code | LS-3075 | LS-3081 | LS-0118 | LS-0206 | LS-7105 | BF-0606 | ||

|---|---|---|---|---|---|---|---|---|

| Sealing temperature | ℃ | 450 | 410 | 430 | 450 | 450 | 485 | |

| Coefficient of thermal expansion |

30-250℃ | ×10-7/K | 36.5 | 74 | 72.5 | 72 | 85* | 73* |

| Density | ×103kg/m3 | 6.91 | 6.89 | 7.05 | 6.82 | 6.37 | 6.05 | |

| Transition point | ℃ | 300 | 300 | 317 | 325 | ー | 365 | |

| Flexion point | ℃ | 330 | 320 | 337 | 353 | ー | 393 | |

| Softening point | ℃ | ー | 365 | 390 | 410 | 400 | 450 | |

| Volume resistivity Log | 150℃ | Ω・cm | 10.8 | 12.2 | 11.2 | 13.2 | 10.4 | 12.0 |

| Color tone | Black | Green | ||||||

| Glass type | PbO and B2O3 (composite) |

PbO, ZnO, and B2O3 (crystalline) |

Bi2O3 and B2O3 (composite) |

|||||

| Application | Alkali-free glass | Soda flat glass, 50 Alloy, and 426 Alloy |

||||||

-

Coefficient of thermal expansion is measured in the range of 30 to 300°C

For lead-free options or additional properties not listed above, please contact us.

Usage Examples

-

Printing and Drying

Combine powder glass with a vehicle and mix thoroughly to form a paste. A suitable vehicle is a low-molecular-weight acrylic resin dissolved in 5% terpineol. For printing, use a stainless steel screen (80–100 mesh). Dry the printed paste at 120°C for 10–20 minutes. -

Temporary Baking

Conduct temporary baking in air or oxygen to eliminate the resin from the coating film. Since the binder decomposes and fires most actively between 320°C and 380°C, increase the temperature gradually within this range. Maintain the peak temperature for about 10 minutes. -

Sealing

Carry out sealing in air or nitrogen.

For further details, please refer to the downloadable document.

Need More Details? Connect with Us!

Related Products

Passivation Glass

Composite Powder for Low Temperature Cofired Ceramics

Granulated Glass for Metal Packages

Powder Glass for Coating, Binding, and Sealing

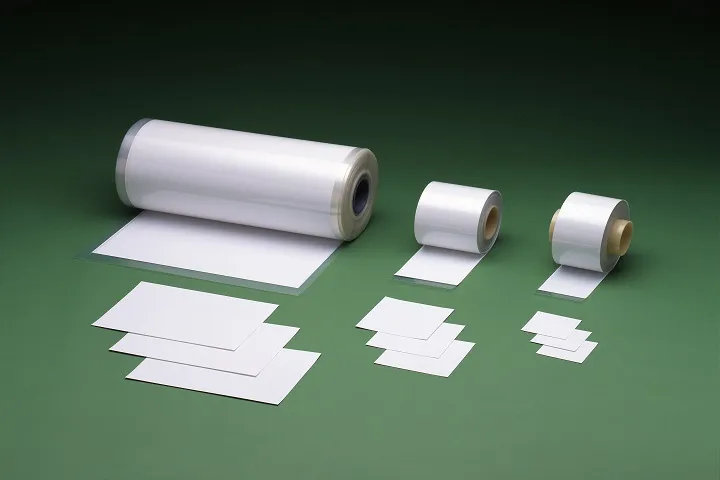

Tablet

Glass Paste

Find Similar Products

Industry

Shape