Glass Engineering

Glass manufacturing processes for carbon neutrality

At the core of our values is “consideration for the environment.” We believe that “having the world’s most efficient processes possible is the key to achieving the world’s most environmentally-friendly manufacturing.” Guided by this principle, we have pursued energy-saving and CO₂ reduction strategies through continuous improvements in quality and productivity. Glass manufacturing consumes significant energy during the melting process, so we have focused on optimizing this stage since our founding.

As demand for carbon neutrality in manufacturing grows, we have developed oxygen combustion and electric melting technologies in-house. These innovations support the development and evaluation of our advanced glass melting furnaces. We believe these technologies can benefit the entire glass industry, not just our company. By leveraging our extensive experience, we will continue to deliver solutions for reducing CO₂ emissions in glass manufacturing.

Oxy-fuel Combustion Technology: NOFC™

Since its introduction in Japan in 1993, our NOFC™ (NEG Oxy-fuel Combustion Technology) has dramatically enhanced the energy efficiency of glass melting furnaces, achieving substantial CO₂ emission reductions. By adapting to hydrogen fuels, NOFC™ also opens pathways to even cleaner manufacturing processes.

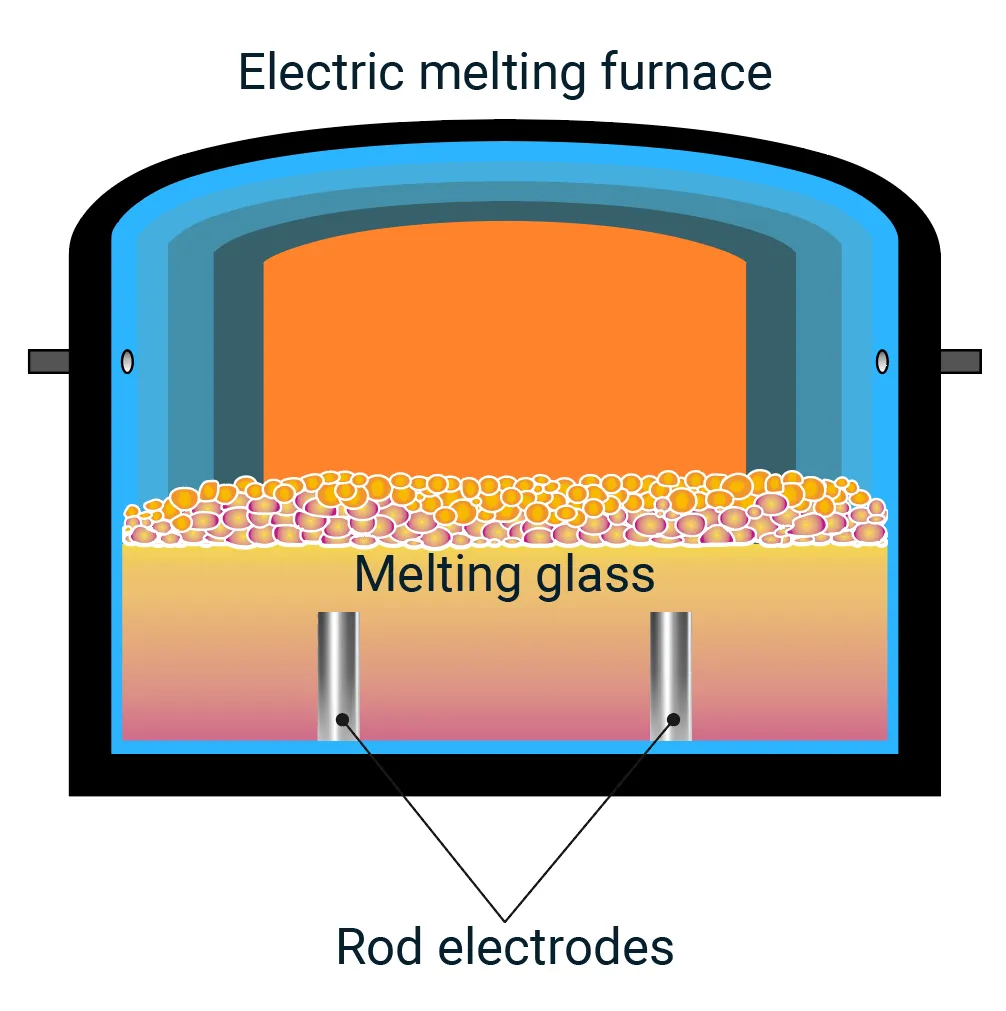

Electric Melting Technology: NEMT™

Our NEMT™ (NEG Electric Melting Technology) delivers all-electric melting furnaces that are highly efficient, high-quality, and eco-friendly. This innovative technology paves the way toward carbon neutrality, transforming the future of the glass industry and the planet.

Combustion Control System: NFCS™

Our NFCS™ (NEG Furnace Control System) optimizes heating conditions for various glass materials. By precisely controlling combustion and electric heating, it enhances glass quality and ensures safe, stable operation through an intuitive user interface. Additional tools like furnace operation monitors and kiln simulations (CFD analysis) support the creation of high-efficiency glass melting processes.

.webp)

NEG Combustion Control System

Improves glass quality by optimally controlling combustion-based heating._sp.webp)

Furnace Monitoring Equipment

Real-time monitoring of furnace and process conditions enhances process safety and efficiency.-

Development of Glass Processing Technology

Evolution of our glass manufacturing process and main product chronology