Furnace Monitoring Equipment

Real-time monitoring for safer, more efficient glass melting

.webp)

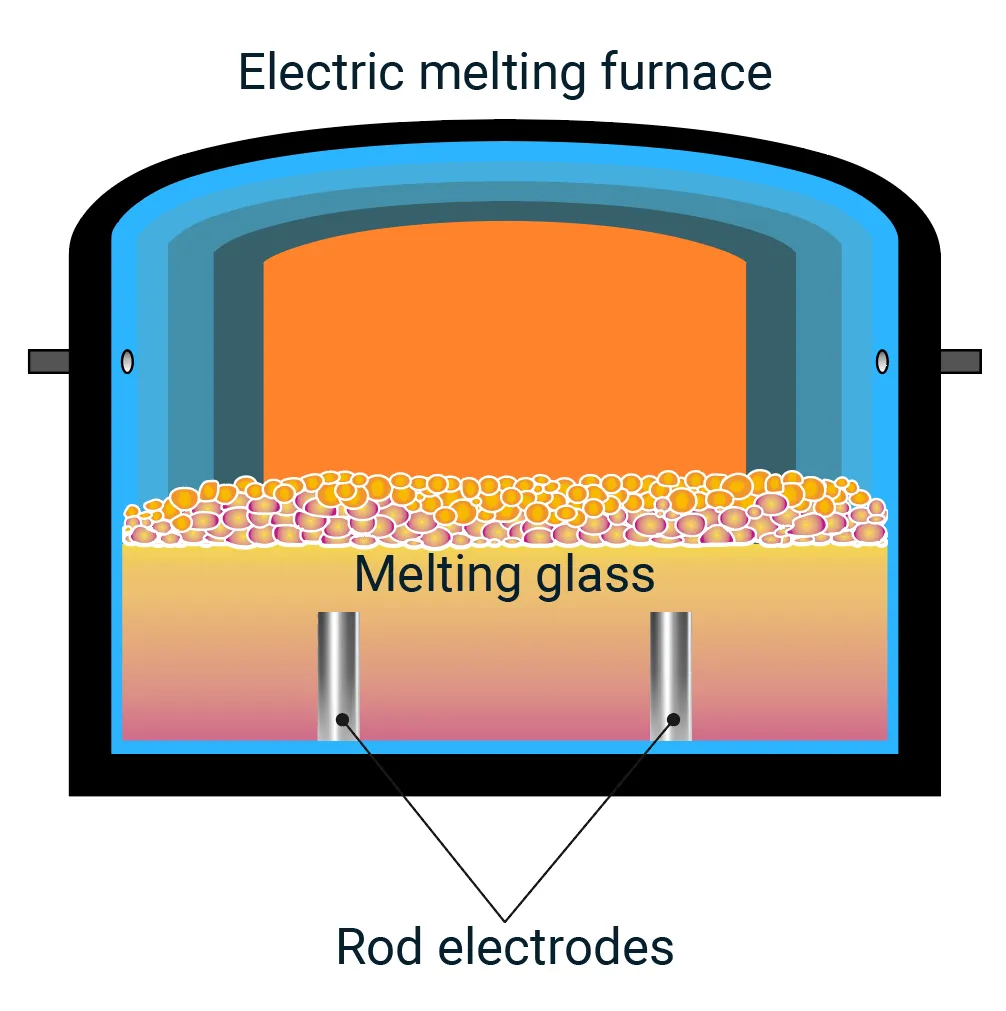

Monitoring the inside of a high-temperature glass melting furnace is challenging with standard cameras. Our specialized furnace monitoring equipment enables real-time monitoring of furnace conditions and processes, enhancing the efficiency of the glass melting process and ensuring safety.

Features

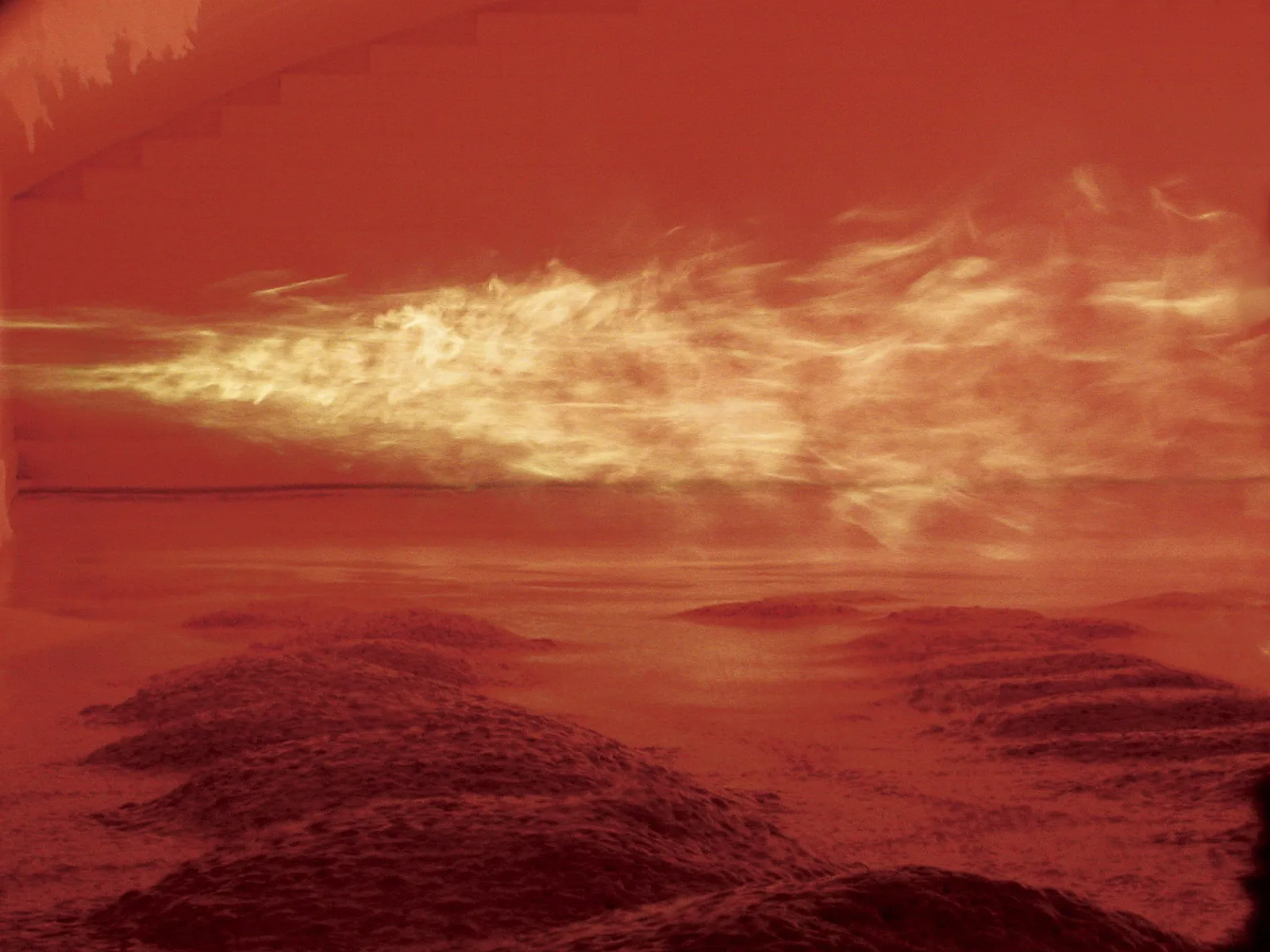

In most glass melting furnaces, burners combust fuel to maintain the high temperatures required for operation. Optimizing this process demands precise monitoring of combustion conditions and careful adjustments of fuel supply to maintain a stable temperature inside of furnaces. However, monitoring systems capable of reliable operation in environments exceeding 1500°C have been extremely limited.

To address this challenge, we have developed an Industrial Television (ITV) system tailored specifically for the harsh environments inside of glass melting furnaces. This system provides real-time visual monitoring of furnace conditions.

By optimally adjusting the amount of fuel supply based on the data obtained from this system, it is possible to improve safety, stabilize operations, and optimize energy efficiency.

-

Compact, lightweight, and easy to install

-

Requires minimal maintenance and improves productivity

-

Adopted in almost all of our melting furnaces

Lineup

Technology Offerings

-

ITV Equipment

*ITV: Monitoring cameras for factories (Industrial Television)

Applications

-

Flat glass manufacturing

-

Bottle glass and Container glass manufacturing

-

Glass fiber manufacturing

-

Special glass manufacturing

.webp)