Electric Melting Technology: NEMT™

As global demand for carbon neutrality grows, the glass manufacturing industry faces the critical challenge of reducing CO2 emissions. By adopting our electric melting technology (NEMT™: NEG Electric Melting Technology), manufacturers can significantly reduce CO2 emissions associated with combustion during glass melting. This groundbreaking technology also contributes to energy efficiency improvement and resource conservation.

Features

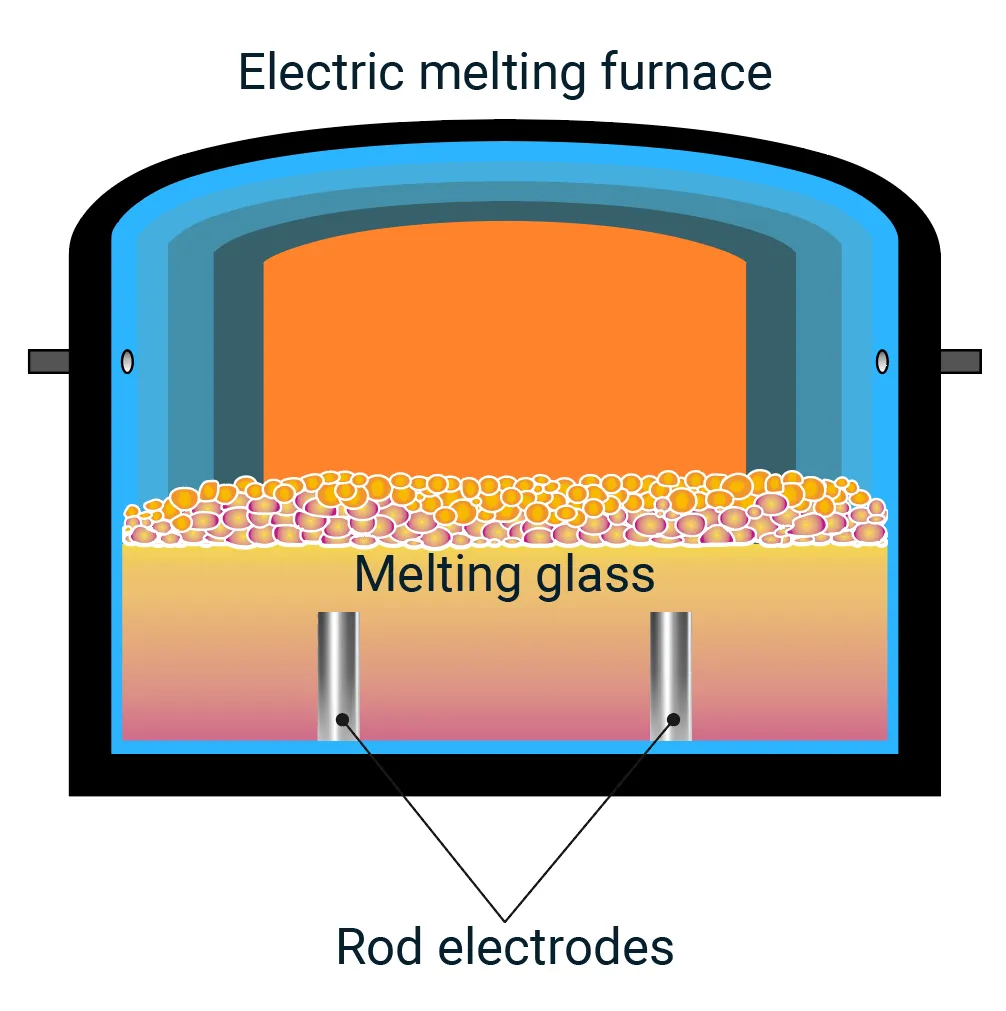

In traditional glass melting, combustion is used to heat materials, leading to significant CO2 emissions. By contrast, NEMT™ replaces combustion with a direct electrical heating method, inserting electrodes into the glass for precise and efficient melting through energization. This innovative technology supports the glass industry’s transition toward sustainable manufacturing while improving energy efficiency and reducing resource consumption.

-

Improved energy efficiency by unifying the energy source to electricity, optimizing the heating process.

-

Enhanced sustainability through the use of renewable energy-derived electricity, further reducing CO2 emissions.

-

Reduced resource consumption by minimizing losses caused by non-uniform heating.

-

Long-term durability and efficiency with electrode systems designed for low heat loss and capable of continuous operation for approximately 20 years.

Lineup

Provided Technologies

-

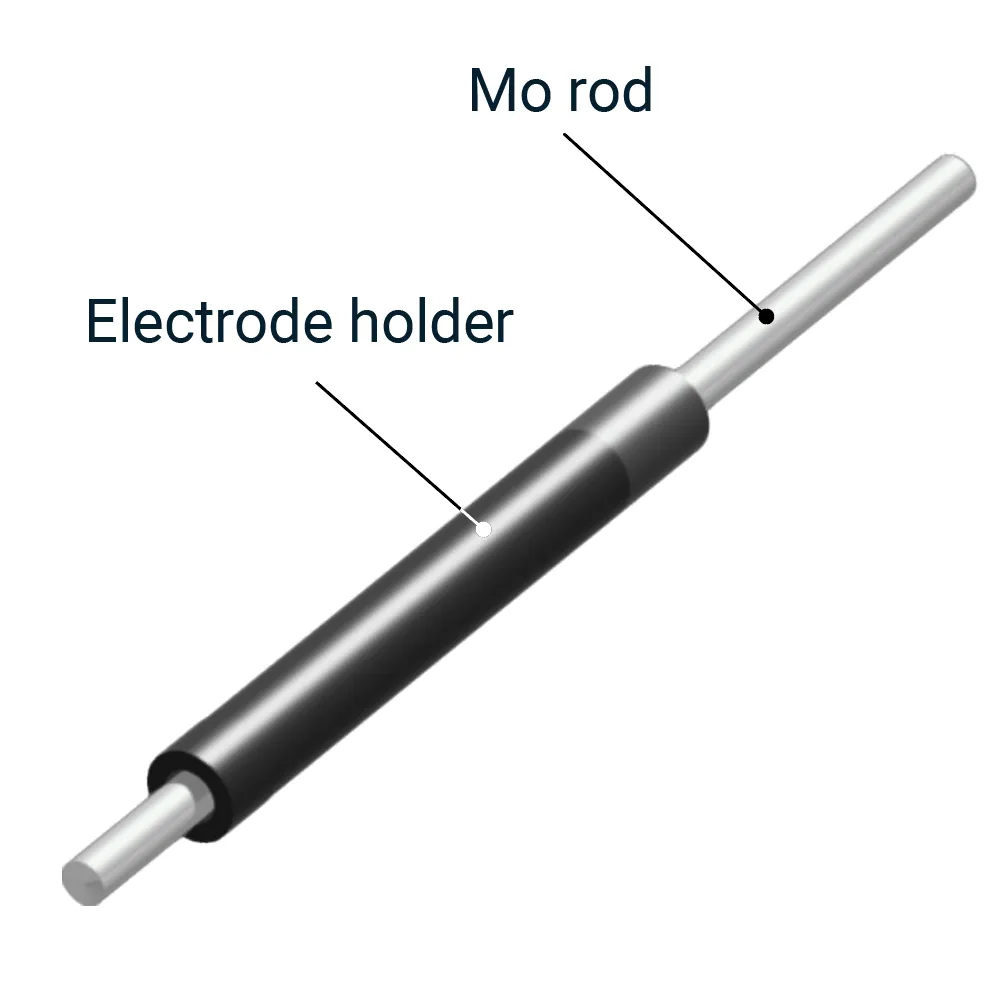

Mo rod electrodes and peripheral equipment (electrode holders, mounting brackets, jack stands, cable clamps)

Water-cooled Electrode Holder

Applications

-

Flat glass manufacturing

-

Bottle glass and Container glass manufacturing

-

Glass fiber manufacturing

-

Special glass manufacturing

.webp)

_sp.webp)