Automotive

From glass for spark plugs and turn signal lamps to cutting-edge components, our special glass has long supported the evolution of automobiles. Today, as Battery Electric Vehicles (BEVs) and Fuel Cell Electric Vehicles (FCEVs) advance, automotive development also accelerates through software innovations like autonomous driving, powered by electronics and ICT (Information and Communication Technology). Special glass plays a vital role in this rapid progress, enhancing both electronic and structural components.

Applications

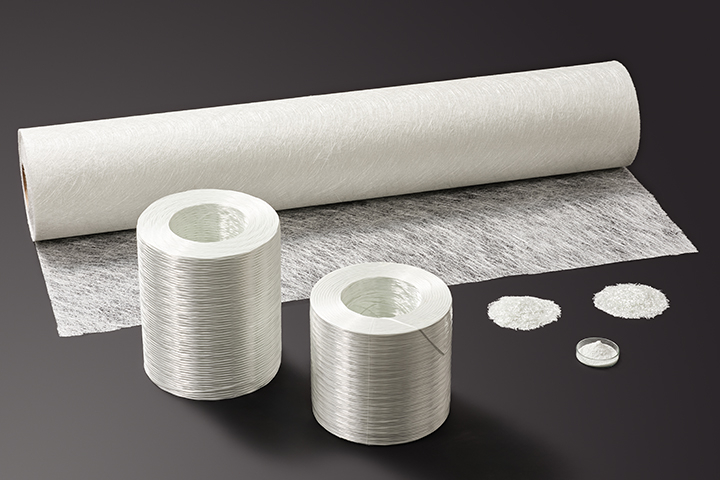

Environmental Considerations Lightweight and Recyclable

Reducing vehicle weight is key to improving fuel efficiency and lowering CO₂ emissions. Our composite materials, made by blending glass fiber with resin, provide mechanical strength comparable to metal and durability while keeping components lightweight. These glass fiber composites are also easier to mold into complex shapes, boosting production efficiency.

Increasing environmental regulations also require the use of recycled materials in resin composites applied in automotive applications. In response, our E Glass Fiber Flat Glass Fiber: INNOFIBER™ combines lightweight performance with recyclability. It offers higher mechanical strength than standard glass fiber, allowing for thinner, lighter composite materials. Even when used with resin composites subjected to multiple material recycles, mechanical strength is still maintained, supporting sustainability without compromising performance.

Sensors

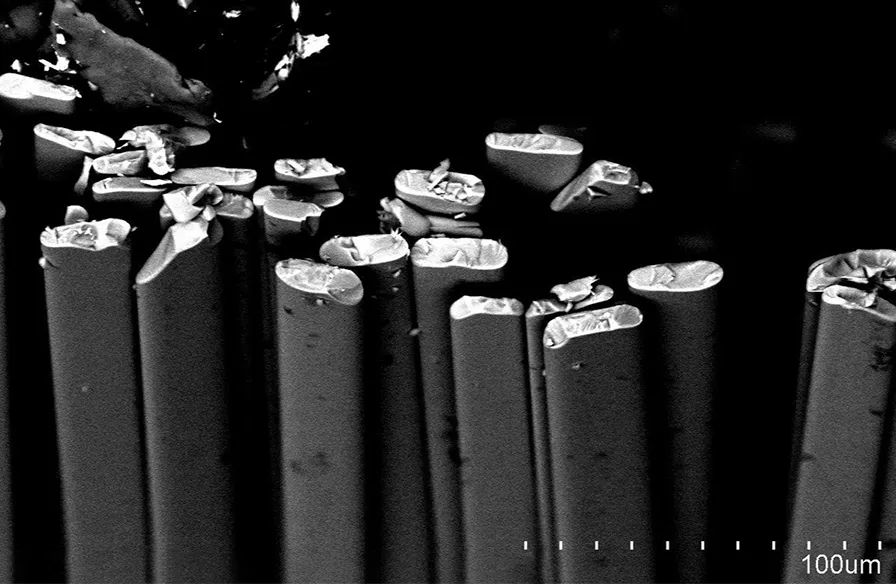

Modern vehicles rely on high-performance sensors, which have greatly improved safety, efficiency, and comfort in recent years. Our powder glass ensures these sensors remain protected from harsh external conditions, offering essential properties for hermetic sealing, insulation, coating, and bonding. Available in granule, paste, and tablet forms, our glass solutions for automotive sensors adapt to a wide range of applications, helping drive the future of smarter, safer automotive technology.

Tablet

This molded product is made by sintering powder glass. It allows users to choose from a wide range of glass options that best suit their needs. Since the glass is a sintered body that has already undergone debinding, it is easy to handle and eliminates the need for previous processes like coating.It can also be used for areas that are challenging to apply or print on, such as narrow holes or thicker coating areas.

Powder Glass for Coating, Binding, and Sealing

This material is ideal for coating various substrates and components. The coefficient of thermal expansion and softening point serve as key factors in selecting the most suitable coating material. Additionally, it functions as a binder for a variety of metal powders and ceramic dielectrics, including those used in solar cell applications. The composition type and softening point can guide the selection process, ensuring compatibility and performance.

Glass Paste

Glass paste is a uniform dispersion of powdered glass on a vehicle.