Glass Fiber

Composite materials that enhance performance when combined with resins, concrete, and other substances. Widely utilized in applications ranging from mobility solutions to social infrastructure.

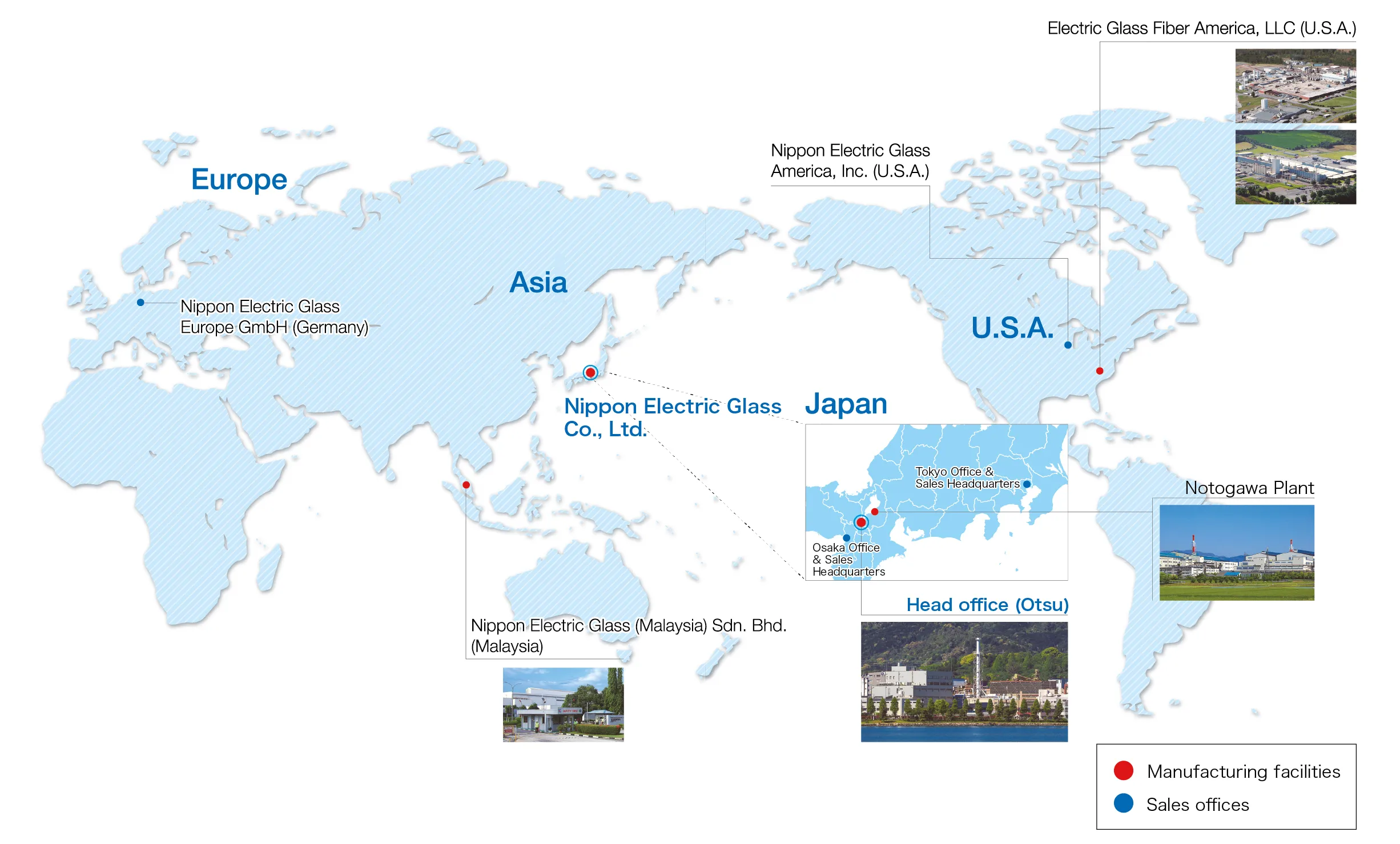

Production and Sales Bases for the Glass Fiber Business

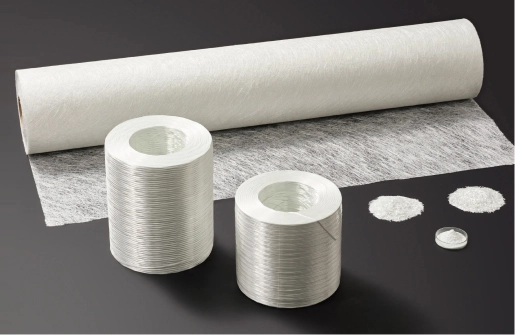

Product List

Low Dielectric Glass Fiber: D2 Fiber Yarn

Engineered as a second-generation low-Df glass fiber, this product delivers superior dielectric performance with a low dissipation factor in a twisted yarn form.

E Glass Fiber

Widely used as a reinforcing material for resins in automotive components, electronic devices, and various other applications.

E Glass Fiber

E Glass Fiber, when combined with resin, enhances properties such as strength, heat resistance, hardness, and dimensional stability. It is widely used across various industries, including automotive parts and housing equipment. Additionally, thanks to the electrical insulation properties of glass, it has played a key role in the advancement of electronic devices, contributing to miniaturization and reduced thickness.

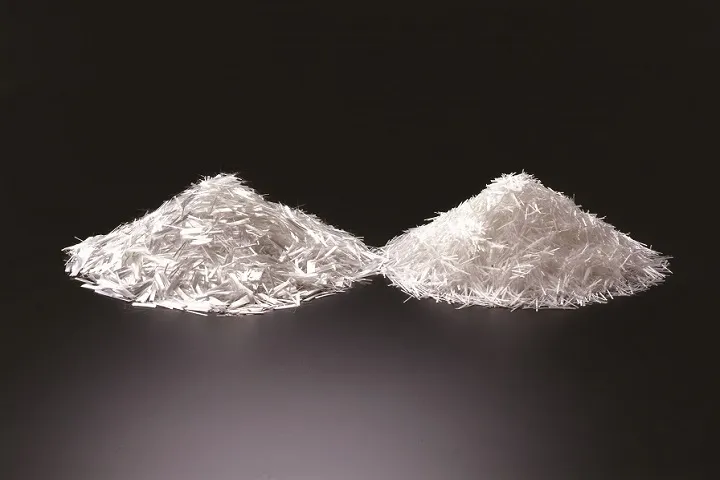

E Glass Fiber Chopped Strands

Chopped strands, created by bundling thousands of E glass fibers and cutting them to a specific length, are coated with a proprietary surface treatment agent that enhances the strength and physical properties of high-performance resins. When combined with these resins in precise ratios, they are widely used globally in FRP and FRTP products, including automotive components and electronic devices.

E Glass Fiber Roving

E glass fiber roving is extensively utilized in various FRP (glass fiber reinforced plastics) products, including housing equipment, automotive components, and synthetic wood. It reinforces various types of thermosetting resins—unsaturated polyester, epoxy, and urethane resins—as well as thermoplastic resins like polypropylene and nylon.

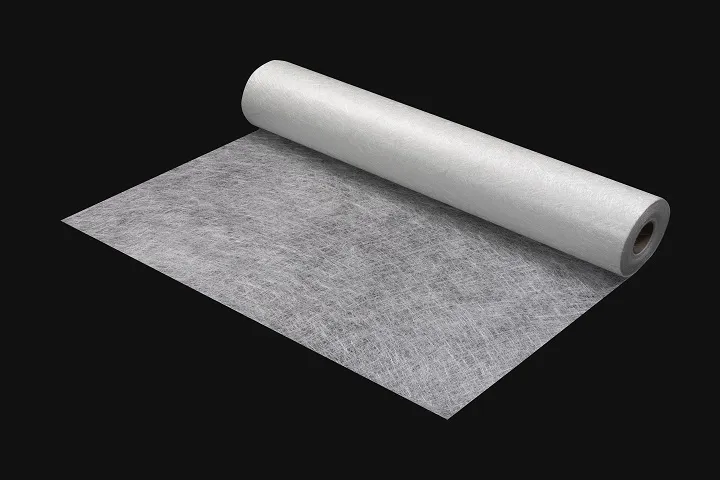

E Glass Fiber Mat

The chopped strand mat is made by cutting E glass fiber, dispersing it into a uniform thickness, and forming a non-woven fabric using a powder sizing agent. By its uniform strength distribution, it is primarily used in automotive ceiling applications, especially for low basis weight products.

E Glass Fiber Yarn for Industrial Materials

E glass fiber yarn is twisted and processed into various forms—cloth, nets, tapes, braids, and more—serving as a basic material widely used in industrial applications, especially for civil engineering and construction. Additionally, yarns created by twisting multiple single yarns offer excellent machinability, enhancing the performance and functionality of the final product.

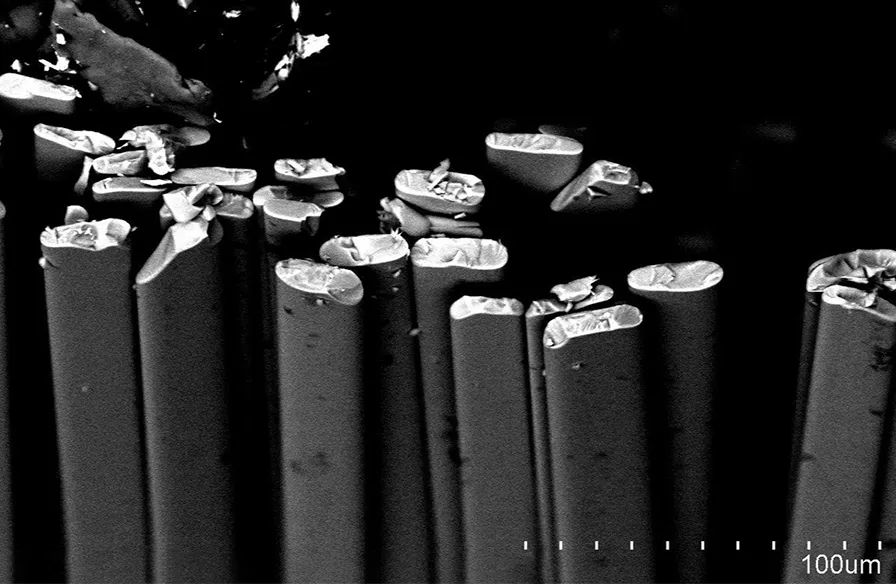

E Glass Fiber Milled Fiber

Milled fibers, made by grinding E glass fibers into lengths ranging from tens to hundreds of micrometers, effectively improve strength while preserving surface appearance and dimensional stability. These fibers are primarily utilized in BMC molding of thermoplastic resins including polycarbonate resins, liquid crystal polymers, and thermosetting resins.

E Glass Fiber Wet Chop

Paper chops, made by cutting E glass fiber into short lengths, are dispersed in a water medium to form a non-woven fabric. After saturation with various resins, the material is molded for use in applications such as building materials and printed wiring boards. These paper chops are notable for their ability to disperse quickly in water and resist reagglomeration, maintaining a uniform dispersion state for extended periods.ARG Fiber: WizARG™

Widely used in the construction and civil engineering industries as a reinforcing material for concrete and calcium silicate.

ARG Fiber: WizARG™

WizARG™ is glass fiber provides exceptional resistance to alkali and acid with a high percentage of zirconia (ZrO2). It is widely used as a reinforcing material in glass fiber reinforced concrete (GRC) and calcium silicate products, as well as a crack-prevention materials in mortar and concrete.

ARG Fiber WizARG™: Chopped Strands

This product consists of 50–200 glass filaments bundled into strands and cut to various lengths. It is used as a reinforcement material in glass fiber reinforced concrete (GRC) and calcium silicate products, as well as for crack control in mortar and concrete.

ARG Fiber WizARG™: Roving

This product is made up of numerous strands, each consisting of 100 to 200 glass filaments (monofilaments) bundled together and wound into a cylindrical shape. It is used in hand-spraying methods and mass production molding equipment for manufacturing glass fiber reinforced concrete (GRC). Ideal for shaping large exterior wall panels and flat surfaces, it is widely used in the construction and civil engineering industries.

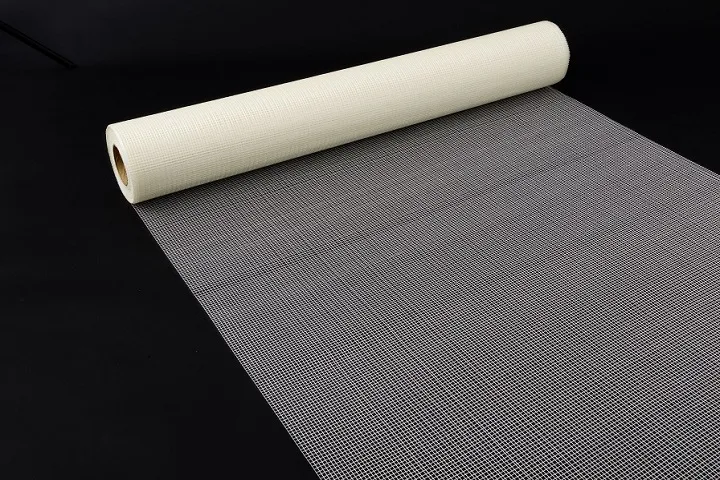

ARG Fiber WizARG™: Scrim

This product is made by weaving strands (yarn or roving) into a mesh. It is used to reinforce plastered mortar, concrete products, and glass fiber reinforced concrete (GRC), as well as for crack control and anti-spalling applications.

ARG Fiber WizARG™: Milled Fiber

WizARG™ milled fiber is produced by grinding alkali-resistant glass fibers, typically several tens of micrometers in diameter, into lengths ranging from tens to hundreds of micrometers. It is ideal for specialized paints that require high alkali and heat resistance and is also used as a viscosity modifier.E Glass Fiber Flat Glass Fiber: INNOFIBER™

Environmentally friendly glass fiber features excellent material recycling capabilities, utilizing flat fibers.