Glass for Chemical Strengthening: Dinorex™

Scratch- and impact-resistant glass

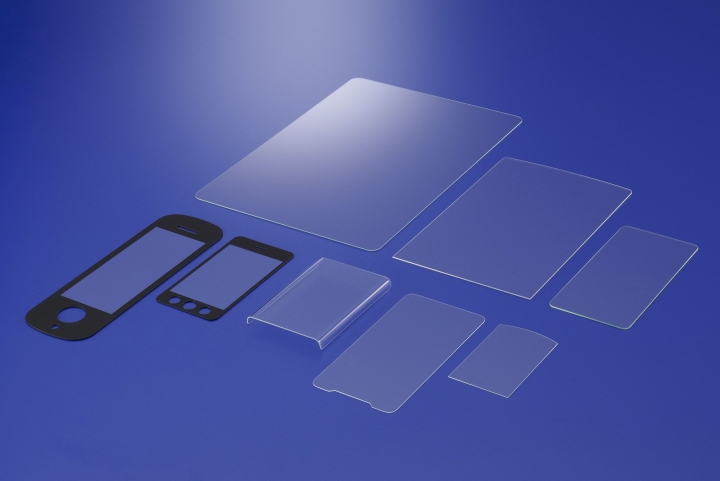

Chemically strengthened glass developed for cover glass in portable devices like smartphones and tablets, as well as automotive displays and other emerging uses. It protects displays against scratches and impacts.

Applications

-

Smartphones

-

Tablets

Features

-

Superior chemical strengthening properties

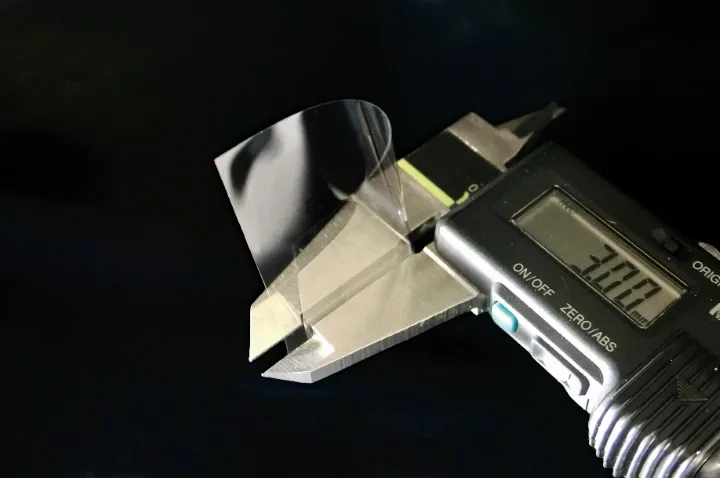

It offers exceptional strength due to its high compressive stress (CS) and deep compressive stress layer (DOL). -

High productivity

Chemical strengthening can be completed quickly, ensuring efficient production. -

High transmittance

Nearly colorless and transparent, it has minimal impact on the color tone and image quality, preserving the clarity and beauty of images and videos.

Reasons for High Impact Resistance

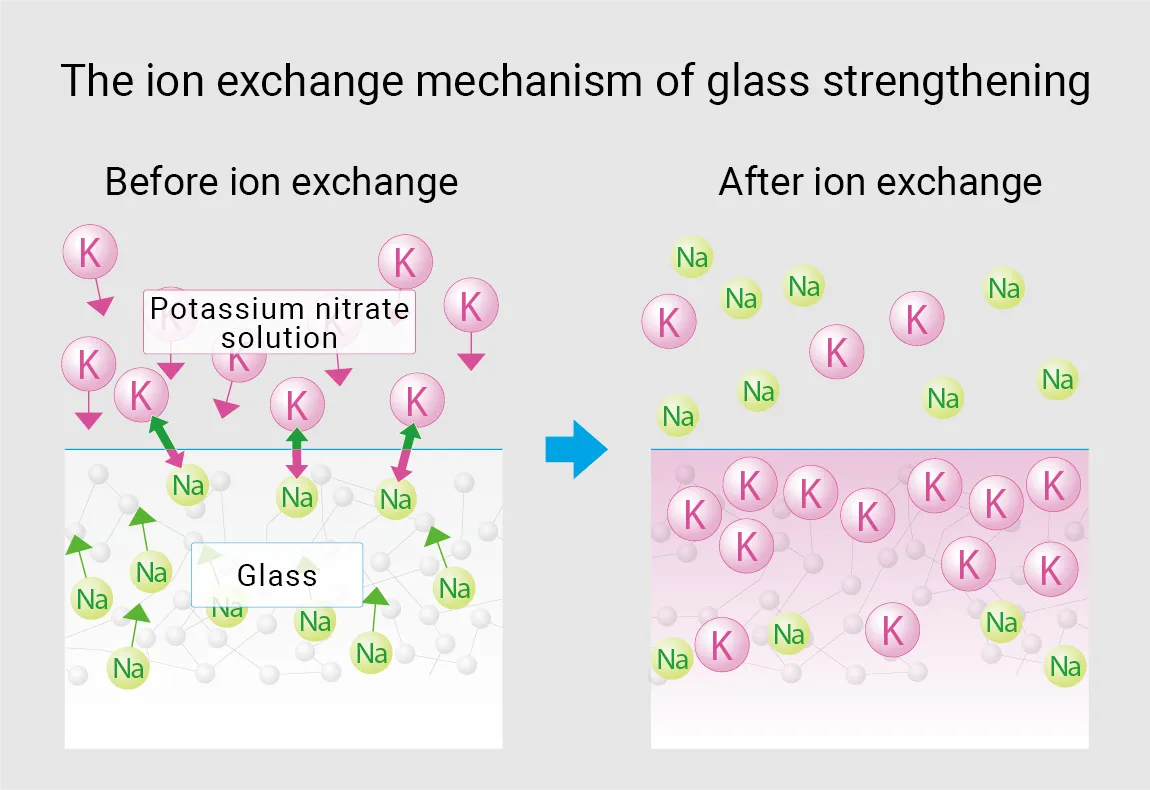

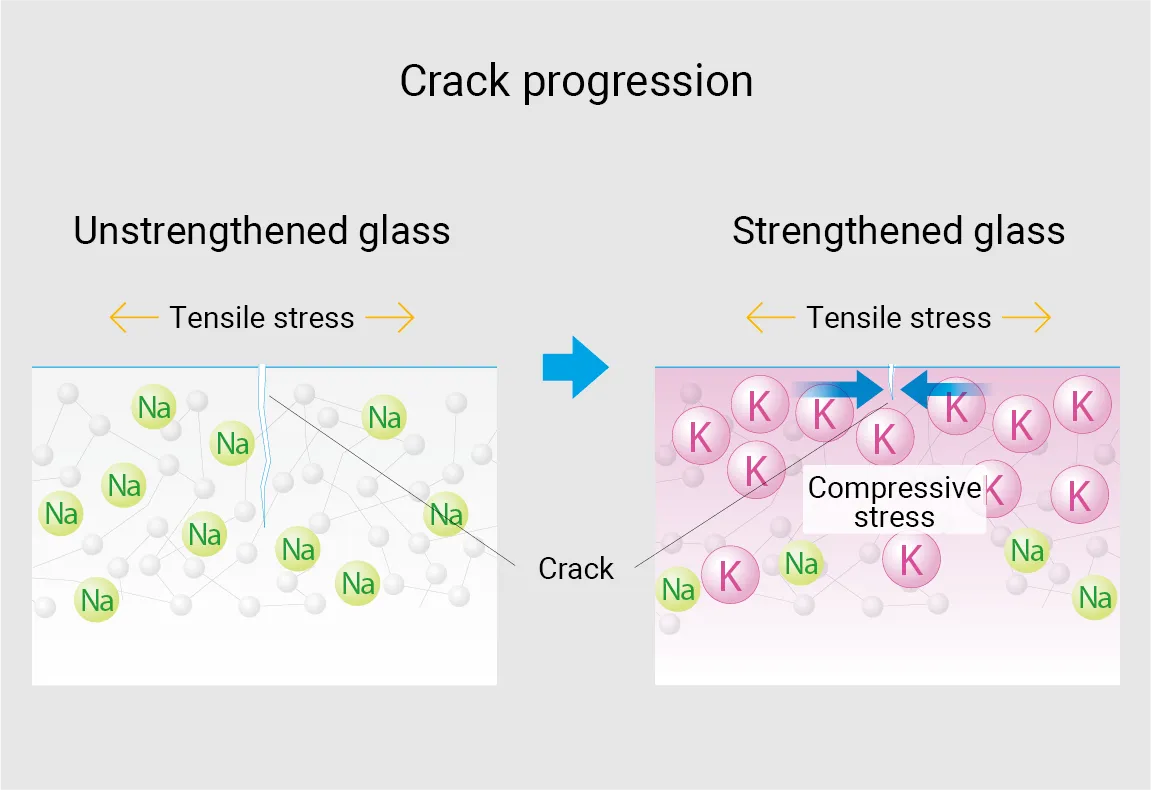

When glass containing sodium ions (Na+) is immersed in a potassium nitrate solution containing potassium ions (K+), the Na+ ions on the surface of the glass are replaced by K+ ions, which have a larger diameter. This process, known as "ion exchange," creates compressive stress on the surface of the glass. This compressive stress enhances the toughness of the glass, making it so resistant that it cannot be broken even when struck with a hammer, for example.

-

What is compressive stress?

When K+ ions, which have a larger diameter, replace Na+ ions with a smaller diameter and enter the surface of the glass, the glass naturally becomes "jammed." This causes the volume of the glass surface to attempt to expand. However, since the overall volume of the glass does not change, a force is generated that compresses the surface in the opposite direction. This is known as "compressive stress." Even if tensile stress is applied to widen a crack on the glass surface, this compressive stress counteracts it, making it difficult for the crack to propagate. As a result, the glass becomes more resistant to cracking.