Development of Glass with Controlled Dielectric Properties

Glass is a dielectric material, meaning that when an alternating electric field is applied, part of the energy is converted into heat, causing dielectric loss. This loss depends on the dielectric properties of the glass, specifically the dielectric constant and the dielectric loss tangent (tanδ). Generally, as frequency increases, so does the loss, and the higher the values of the dielectric constant and the dielectric loss tangent, the greater the loss.

Low-loss dielectric properties are essential for glassware used in applications such as printed circuit boards and low-temperature co-fired multilayer substrates. As a result, we develop and offer a variety of glass types with dielectric properties specifically designed to meet the needs of these applications.

Sidebar: Understanding Dielectric Properties

Dielectric properties describe how a material responds when exposed to an electric field. Key characteristics include the dielectric constant (ε) and the dielectric loss tangent (tanδ).

The dielectric constant represents a material's ability to become electrically polarized in response to an applied electric field, relative to the strength of the field. The relative dielectric constant (εr) is most commonly used, comparing the material's dielectric constant to that of a vacuum, which is defined as 1.

The tanδ indicates the amount of electrical energy lost as heat within a dielectric material. A lower tanδ value means less energy is lost, while a higher value results in more energy absorption. This can lead to inefficient signal transmission and higher power consumption.

In general, the higher the tanδ, the greater the energy dissipation (heat generation) and the overall loss in the material.

Dielectric loss can be calculated using the following formula:

Dielectric loss = proportional constant × frequency × √dielectric constant × tanδ.

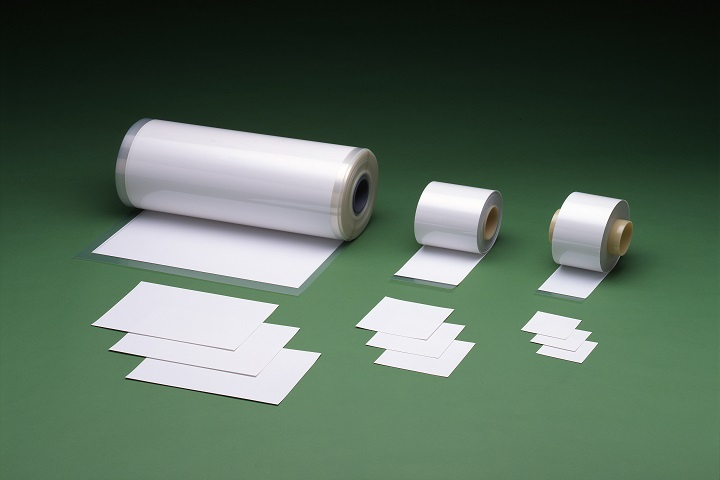

Low Dielectric Loss Glass Materials

In recent years, materials used in circuit boards—such as those for semiconductor package substrates, low-temperature co-fired multilayer substrates, and high-frequency radar applications—have increasingly required low transmission and dielectric loss, characterized by a low dielectric loss tangent (tanδ) and dielectric constant. To meet these demands, we develop and provide a range of low dielectric loss glass materials, including powder glass for low-loss coatings, binding, and sealing, composite powders for Low Temperature Co-fired Ceramics (LTCC), and glass-ceramic core substrates like GC Core™.