Aerospace

In the aerospace industry, glass is a critical material. Aircraft camera lenses, satellite observation devices, and other aerospace components need glass with high durability and transparency to function optimally. Thanks to its heat resistance, dimensional stability, and excellent optical properties, glass can meet the industry’s stringent requirements. Its unique qualities also make it ideal for protecting satellite solar panels. As aerospace technologies advance, the demand for even higher-performance glass products continues to grow, driving ongoing innovation.

Applications

Satellite Mounted Solar Cells Panel Cover

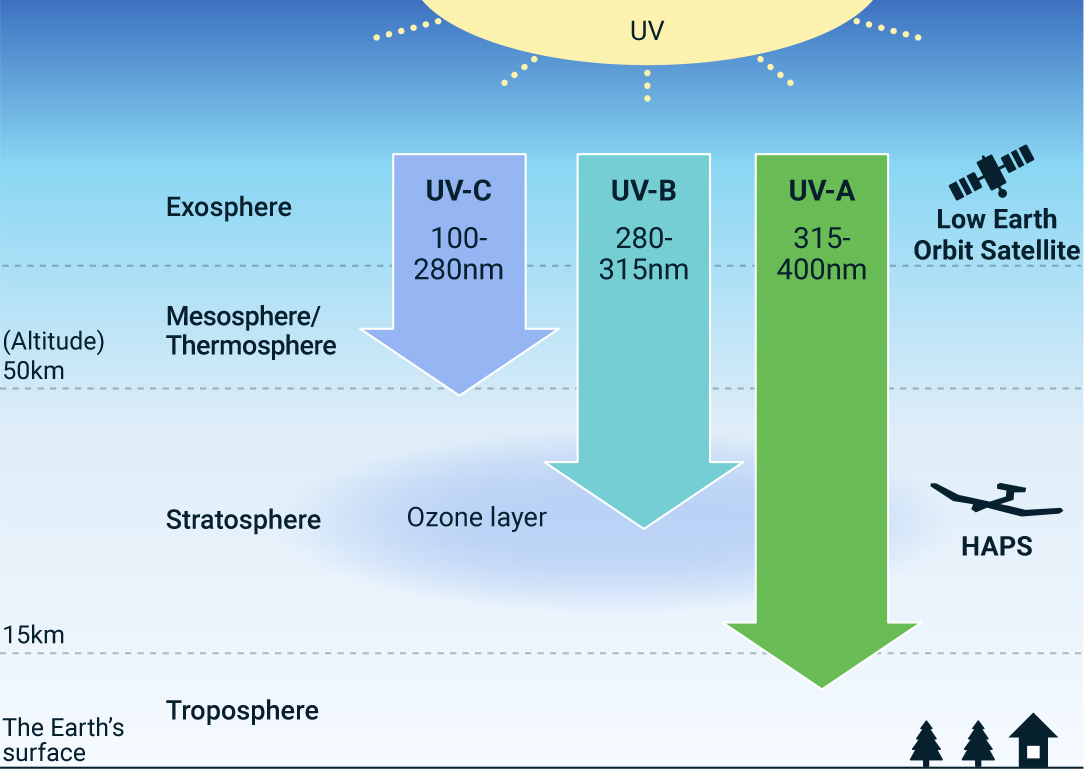

In recent years, Low Earth Orbit (LEO) satellites and High Altitude Platform Stations (HAPS) have emerged as revolutionary communication solutions. LEO satellites have low launch costs and orbit within 2,000㎞ of Earth, gaining attention as a cost-effective way to expand internet connectivity. Meanwhile, HAPS are unmanned aircraft capable of sustained flight in the stratosphere at around 20 kilometers, providing communication and observation capabilities for regions without ground infrastructure or during disasters. HAPS offer wide coverage at lower costs, making them highly effective in critical applications.

Our ultra-thin glass with UV shielding properties plays a crucial role in these applications. It effectively protects solar cells from the intense ultraviolet radiation present in both Low Earth Orbit (LEO) satellites and the stratosphere, the operating altitude of HAPS. The UV protection in our ultra-thin glass helps prevent damage to solar cells, extending their lifespan and ensuring reliable performance.

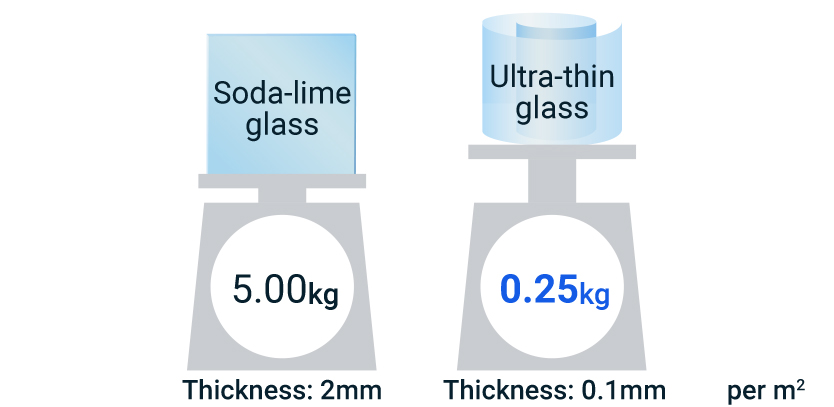

Additionally, our glass is remarkably lightweight—less than 1/20th the weight of conventional glass per square meter. This significantly reduces the overall weight of the equipment. For LEO satellites, this allows for maximum payload capacity. For HAPS, it enhances energy efficiency, extends flight duration, reduces power consumption, and lowers operational costs.

Information and Communication

Astronomy has seen remarkable progress with the development of observational techniques across the full wavelength range, including X-rays, radio waves, and infrared radiation. The introduction of space telescopes and other observational instruments has further accelerated our understanding of the universe.

Enhancing the performance of these instruments has been one of the most important challenges, and the use of optical materials with a high refractive index has led to a dramatic increase in their capabilities.

High-performance observation instruments rely on such optical materials to achieve greater precision. One example is chalcogenide glass, used in LWIR transmission glass.

Our arsenic- and selenium-free chalcogenide glass is used in green LWIR lenses. In addition to press processing, it can be used for polishing and cutting, offering flexibility from design to assembly—all managed in-house at NEG. This glass is poised to support next-generation space telescopes, helping us explore and understand the cosmos more deeply.

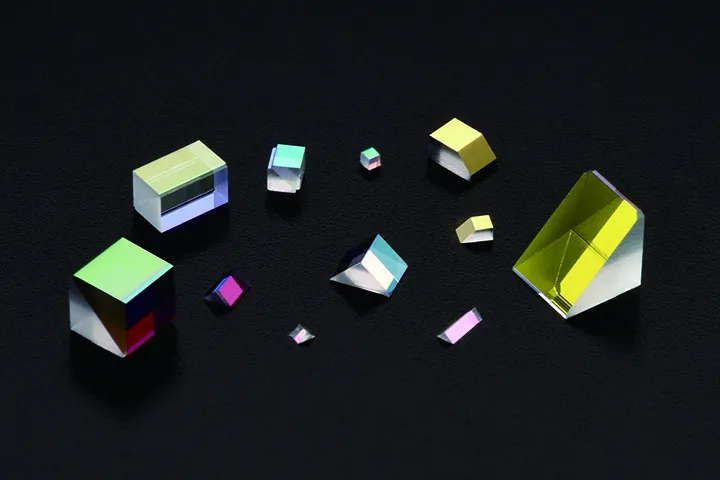

The optical inter-satellite communication system uses light to transmit data between satellites and the ground. These systems require precise alignment of optical signals to ensure high-speed, accurate communication. Our micro prisms facilitate this by allowing fine adjustments to the direction and intensity of light signals.

Available in a variety of shapes and coatings, including anti-reflection coatings, high-reflection coatings, and polarizing beam splitters, our micro prisms reduce signal attenuation and distortion. This ensures reliable, high-quality communication, supporting the growing needs of modern space technologies.

IR Transmitting Glass

Our unique chalcogenide glass is free from hazardous substances like arsenic and selenium. It has excellent infrared transmittance and is available from prototyping to mass production with our in-house production.