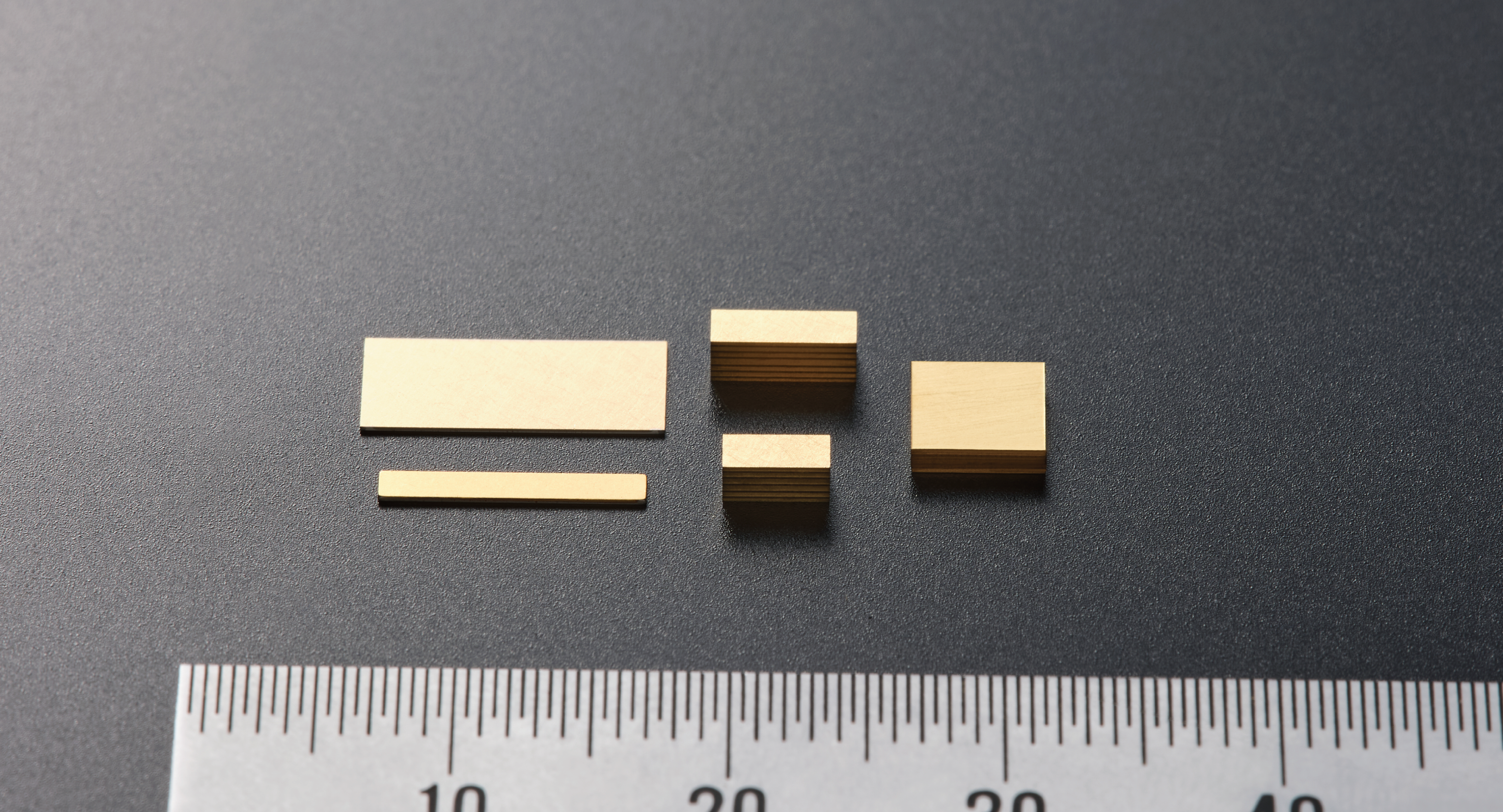

Submount with AuSn solder

Submount with AuSn solder

A submount with AuSn solder coating for easy customer mounting; Cu/Mo laminate substrates offer higher thermal conductivity than CuW and CuMo, while Graphite+Cu provides even higher ultra-high thermal conductivity properties.

Features

-

Reliable and strong joint strength

-

Composition ratio of gold and tin and thickness can be adjusted

-

Composition of base coating (metallization coating) can be adjusted.

-

Pattern deposition can be applied.

-

Material can be selected according to the desired properties.

Applications

-

Heat sinks for high-power LDs

Material Properties

| Substrate | Content ratio | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (×10-6/℃) |

|

|---|---|---|---|---|

| Coating thickness direction | Surface direction | |||

| CuW | W 90wt% | 174 | 174 | 6.4 |

| W 80wt% | 206 | 206 | 8.3 | |

| CuMo | Mo 85wt% | 130 | 130 | 6.6 |

| Mo 65wt% | 207 | 207 | 8.0 | |

| Cu/Mo stacked substrate | Mo 40wt%*1 | 230 | 220 | 6.6 |

| Mo 20wt% | 291 | 334 | 7.4 | |

| Mo 10wt% | 335 | 369 | 11.8 | |

| Mo 5wt% | 362 | 381 | 14.8 | |

| Graphite+Cu*2 | ー | 50 | 800 | 4.0-8.0 |

-

Cu/Mo stacked substrate with Mo 40wt% shows higher thermal conductivity than CuW and CuMo with the same CTE.

-

Graphite+Cu has ultra-high thermal conductivity of 800W/m-K while matching CTE to LD chips.

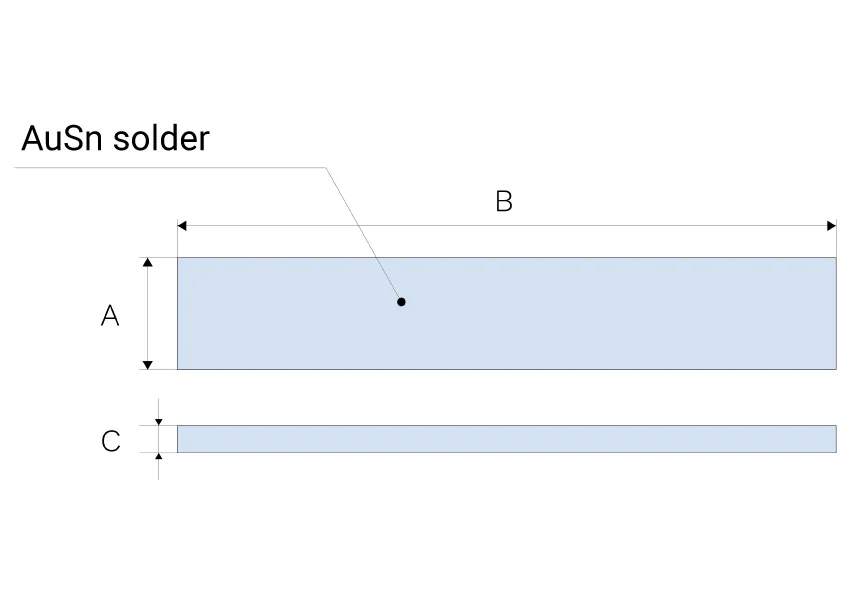

Specification Example

Dimensions (mm)

A=1.50, B=10.00, C=0.25

Composition ratio

Au : Sn = 78 : 22 (wt%)

Coating thickness

5μm

Event Information

We will be exhibiting at the following events.

Need More Details? Connect with Us!

Find Similar Products

Industry

Shape