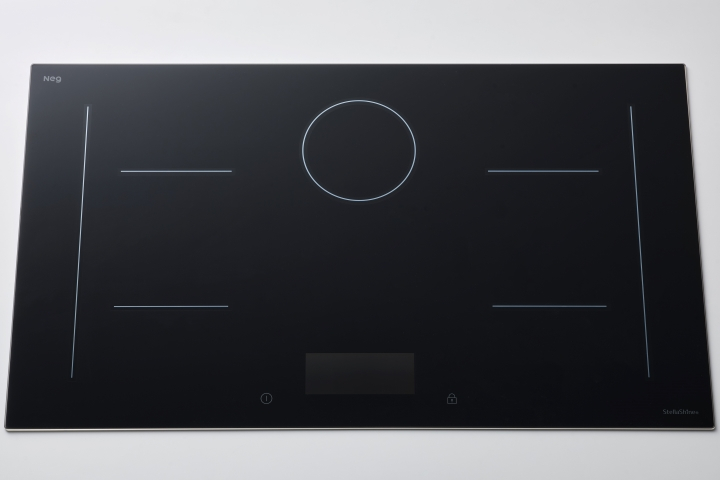

Glass-ceramics for Cooking Appliance Top Plates: StellaShine™

Glass that brings color and function to your kitchen

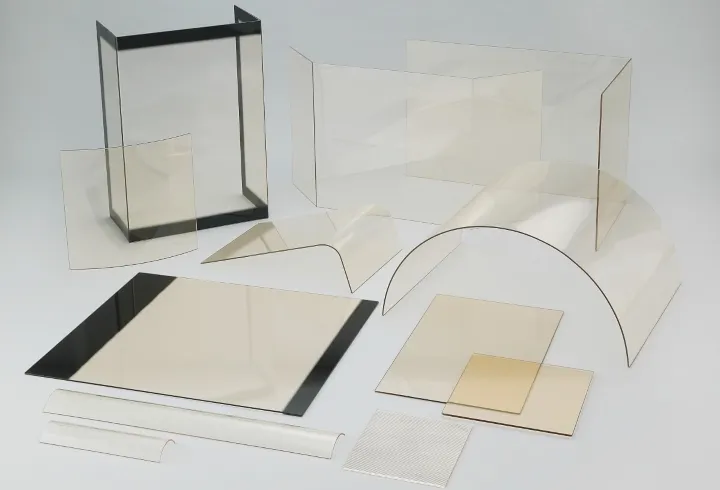

This glass offers exceptional thermal shock resistance, remaining intact even when cold water is poured on it after being heated to 800°C. Its durability under repeated heating makes it ideal for cooktop plates. Available in a variety of colors, it also supports matte and gradient printing.

Features

-

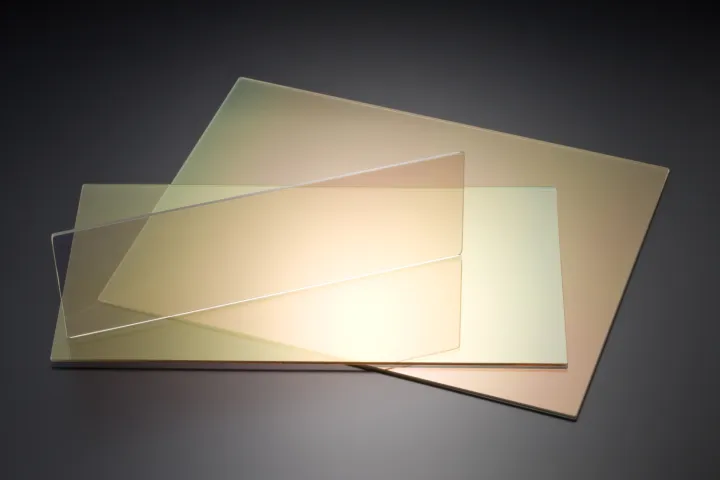

Wide variety of colors

We offer glass in a range of shades, from classic black, white, and gray to vibrant options like pink, blue, and green. -

Matte and gradient printing

Enhance the glass's elegance and functionality with matte finishes or smooth gradient effects. -

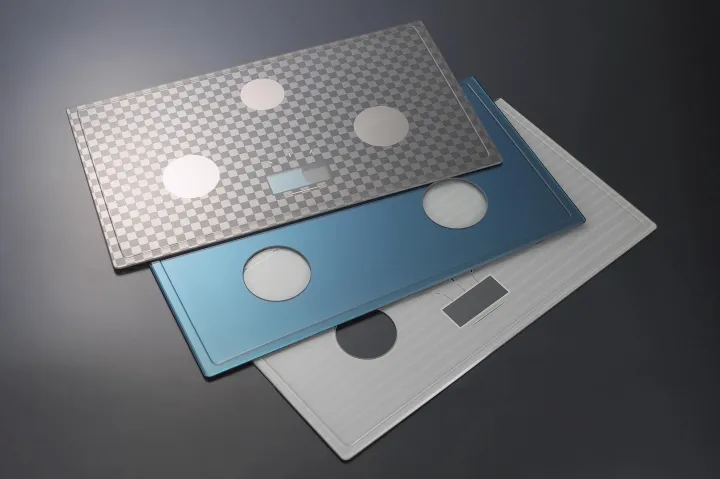

Pattern printing

Custom patterns can be printed to meet specific design requests. -

Excellent thermal shock resistance

With exceptional heat and thermal shock resistance, the glass remains safe and durable even during sudden temperature changes, such as spills. -

Eco-friendly

Free from harmful substances like arsenic or antimony, this glass is safe for the environment.

Product Lineup

Color Variations

-

Additional glass colors are available upon request. Please don't hesitate to contact us.

Matte Printing

Properties

| Glass type | N-0 | N-11 | |||

|---|---|---|---|---|---|

| Color | Transparent | White | |||

| Thermal properties | Coefficient of thermal expansion | ×10-7/K | 30~380℃ | -1 | 10 |

| 30~750℃ | 1 | 12 | |||

| Specific heat | J/kg・K | 25℃ | 800 | 800 | |

| Thermal conductivity | W/m・K | 25℃ | 1.6 | 1.6 | |

| Heat resistant temperature* | ℃ | Continuous | 750 | 850 | |

| Short term | 850 | 950 | |||

| Thermal shock resistant temperature** | ℃ | 100 × 100 × 3 mm plate | 800 | 550 | |

| Mechanical properties | Density | ×103kg/m3 | 2.5 | 2.5 | |

| Bending strength | MPa | JIS R 1601 | 170 | 220 | |

| Vicker’s hardness Hv(0.2) | 700 | 800 | |||

| Young’s modulus | GPa | 94 | 86 | ||

-

Heat resistant temperature: The temperature at which a 100 × 300 × 3.8t mm specimen deflects by 1mm under its own weight after 1000 hours of continuous heating with a 280mm distance between fulcrum points, or after 24 hours of continuous short-term heating.

-

Thermal shock resistance temperature: An approximate value determined through testing where a heated sample is rapidly cooled by immersion in water. This value may vary depending on the product’s wall thickness and shape.

-

The data values are measured values, not guaranteed values.

Need More Details? Connect with Us!

Related Products

Find Similar Products

Functions and Characteristics

Shape